MPS protective coating

MPS protective coating

Effective protection for components

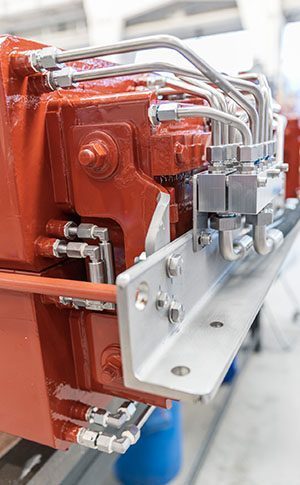

The MPS protective coating (Moisture Protection System) is an essential component of the REO insulation system and one of the biggest unique selling points of REO components. The MPS protective coating developed by us is exclusively available from REO. It reliably and permanently protects your components from a variety of environmental influences. To provide the necessary protection outdoors against abrasion from the pantograph, brake dust, metal abrasion, snow and ice, our components receive this special protective coating in addition to VPI impregnation. This offers the possibility of exposing the components housed (IP20) to the unfiltered cooling air. A major advantage, for example, with regard to the flexibility of railway designs. From pollution degree PD3A onwards, REO relies on this MPS protective coating.

REO applies the coatings and paints only under strict compliance with the necessary safety measures. Complex filter systems and safety standards ensure that the impact on both people and nature is reduced to a minimum.

REO offers the silicone coating as REO Xtreme or REO Mix & Match.

Benefits

- Best protection against moisture

- Very good protection against rockfall

- High abrasion resistance (desert sand resistant)

- Suitable for pollution degree > PD4a

- High tracking resistance (CTI > 600V)

With REO Mix & Match, you can choose from a wealth of options to get the optimal product for your application.

The REO experts are always available to answer any questions.

REO Technologies

REO: A reliable partner

As one of the world’s leading manufacturers of inductive components, REO specialized early on in the challenge of EMC problems in frequency converter-controlled drive systems. In collaboration with manufacturers of drive systems and mechanical engineering companies, we have innovatively driven this development forward over the last four decades. Our EMC solutions are specially tailored to these drive systems. Thanks to our comprehensive vertical range of manufacture and the expertise in filtering such systems, which is bundled in our own development center, we can offer our customers the best possible EMC solutions. In addition to EMC tests and tests under extreme environmental conditions, we also carry out shock and vibration tests in our own laboratory.

For particularly demanding projects, we at REO develop tailor-made solutions in close coordination with our customers. Our many years of experience and constant innovation, inspired by the diverse requirements from industries such as railway technology or wind energy, enable us to create the ideal voltage for our customers’ products.