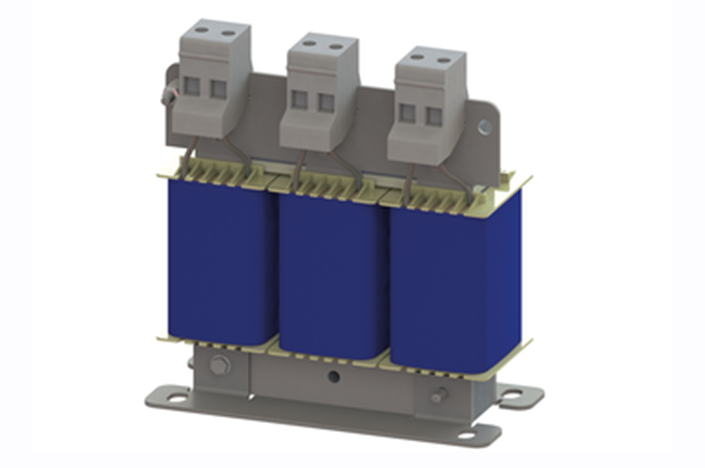

REO has launched two new series of line chokes, the N CNW 905 and N CNW 903, for reliable suppression of harmonic currents. These series integrate seamlessly into REO’s already broad portfolio of line chokes, providing a valuable addition. The new line chokes have been designed to require fewer components, thus reducing copper usage, achieving smaller dimensions, and simultaneously lowering power loss by up to 25%.

This reduced material usage in the N CNW 905 and N CNW 903 is made possible by innovative edge-winding technology. With increased effectiveness and lower weight, the new series with edgewound coils feature highly efficient cooling due to their single-layer design—especially with forced cooling. Thanks to improved cooling, aluminum conductors can be used as a substitute for copper conductors, depending on the design. The reduced weight and smaller dimensions are possible due to the reduction of skin and proximity losses. Edge winding is particularly suitable for semiconductors based on new materials such as silicon carbide (SiC) and gallium nitride (GaN). Due to the lower winding capacitance, the edgewound coil can also be used at higher frequencies. Almost no insulating material is needed, which increases the lifespan.

Less material, and especially less copper, also translates into a lower overall product price. In combination with automated manufacturing, production costs can be further reduced. This significantly shortens the payback period. REO is convinced that this technology offers a long-term advantage over conventional methods, which is why manufacturing capacities are being further increased.

REO can equip the devices with an ingress protection (IP) rating of up to IP66, guaranteeing dust-tightness and protection against water jets. This means that REO chokes can also be mounted outside a main control cabinet.

“The use of line chokes has long been a reliable method for reducing the harmonic currents that a typical variable speed drive draws,” explains Steve Hughes, Managing Director of REO UK, adding: “Improving the power factor (PF) and reducing harmonic currents in the VFD’s mains supply are key to increasing efficiency. For example, a typical 22 kW drive has a PF between 0.7 and 0.8 and an RMS input current of about 43 amps when the motor is loaded. We have found that by using an REO input choke to reduce harmonics, this PF can be improved to about 0.89 and the RMS supply current can be reduced to about 35 A, which can lower the electrical energy required to drive the motor by over 18 percent. .