- News

Liquid-cooled Braking Resistors in Electric Vehicles

Manufacturers can take advantage of REO’s liquid cooling technology for braking resistors without having to worry about the power-to-weight ratio.

A basic principle of good product design is the power-to-weight ratio. This concept is particularly important for the design of components for electric vehicles, such as braking resistors. This is because electric vehicles already have a high basic weight in their construction due to the lithium-ion batteries and electric motors. Weight optimization of vehicle components is therefore an important aspect of development. Steve Hughes, Managing Director at REO UK, explains the advantages of liquid-cooled braking resistors and provides an insight into why REO manufactures them to be weight- and space-optimized.

The power-to-weight ratio is a calculation applied to engines and mobile power sources. It enables a comparison between different units or designs. To calculate the power-to-weight ratio, the power of a drive or motor is divided by the total weight of the vehicle. The result is a vehicle size-independent variable that is often used as a measure of the overall performance of a vehicle. The greater the weight of the individual components, the higher and therefore “worse” the power-to-weight ratio. Saving weight in the construction of components is therefore an important aspect of reducing the power-to-weight ratio.

Braking resistors from REO

A central component of the design of all electric vehicles is the braking resistor, which dissipates heat and slows down mechanical systems in a process known as dynamic braking. There are two forms of dynamic braking: rheostatic and regenerative braking. In rheostatic braking, the energy is dissipated as heat in a resistor. In contrast, in regenerative braking, the electrical energy is fed back into the system. Braking resistors with regenerative braking are more expensive due to their design.

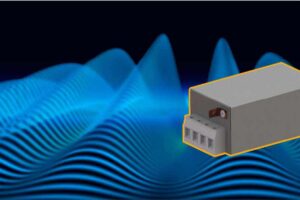

Both systems have in common the development of heat, which must be dissipated from the system. In order to improve the power dissipation, resistors are therefore often equipped with active fans. Thanks to advances in liquid cooling technology, however, electric vehicles are increasingly using solutions that dissipate heat by means of water or a coolant. With this technology, REO can design and build highly efficient cooling systems that are around 80 percent smaller than conventional braking resistors. Manufacturers of electric vehicles appreciate the more compact dimensions, lower weight and improved cooling capacity when used in their vehicles.

The greatest advantage of liquid cooling lies in the physical properties of the coolant used: liquids have a higher density than air, which leads to a higher heat carrying capacity. The temperatures and loads of electrical components are greatly reduced and the service life is significantly extended. The elimination of a large surface area, which is required for ambient or forced air cooling, also means that liquid cooling systems take up less space and can therefore be designed much more compactly. In addition, the water-cooled resistor is virtually inaudible due to its encapsulated design. This is in contrast to conventional resistors, which can generate audible noise at harmonic frequencies of the DC ripple current. This can be disruptive in areas where they are in close proximity to people.

However, where electricity flows and liquids are used, there is a particularly high demand for safety. REO therefore separates the cooling system or the coolant from the electrical circuit. This ensures electrical isolation and the component can continue to run without coolant for a short period of time. This is important in order to enable a safe shutdown of the system in the event of a coolant problem.

REO relies on liquid cooling in many modern series due to these advantages. A good example of this is REO’s BW D 158 series of aluminum-coated water-cooled resistors. The components are designed for a continuous power dissipation of up to 60 kW and sealed in an anodized aluminum housing to protection class IP65. All connections and fixings are made of either stainless steel or anodized aluminum to protect against corrosion. REO offers the resistors between 2 and 850 ohms and, depending on the size, with a nominal power of 1 kW to 60 kW. The nominal voltage of the component is 1 kV in all cases.