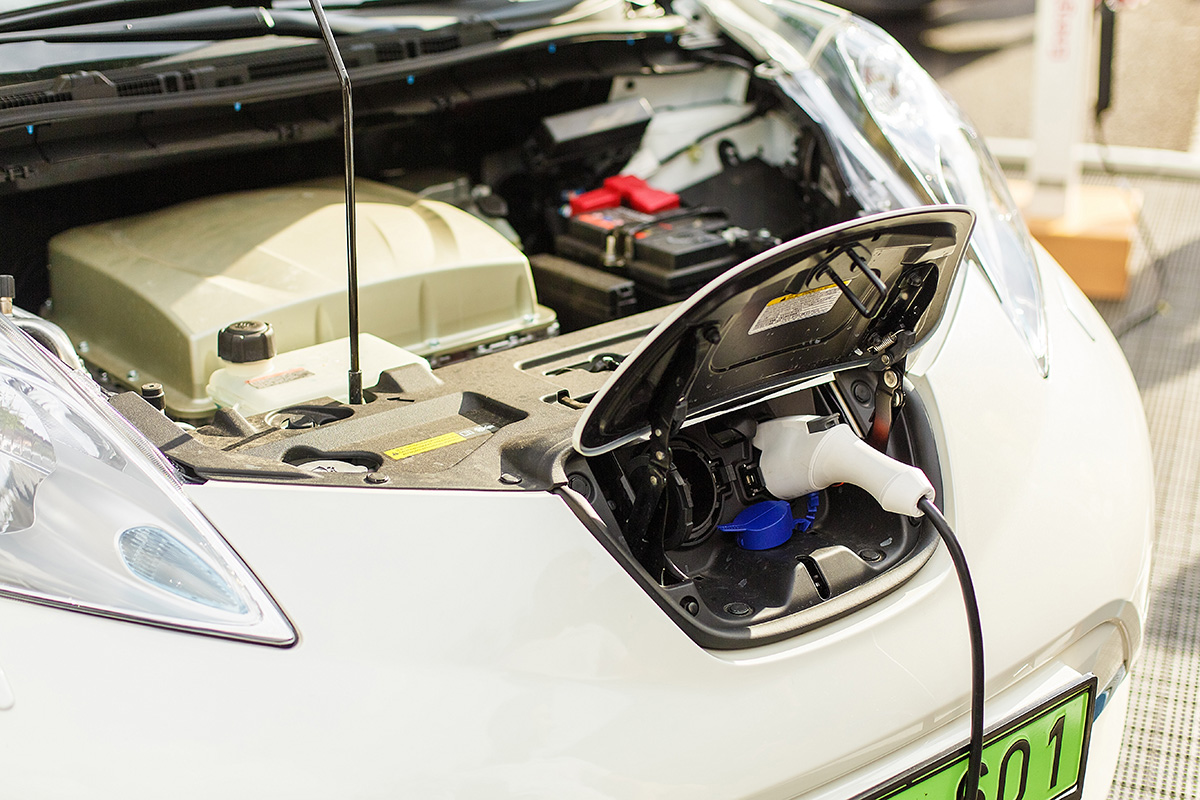

REO UK, a specialist in electric vehicles, recently supplied water-cooled brake resistors for an electric vehicle designed for harsh environments. The standard BWD 158 brake resistor series converts conventional diesel-powered internal combustion engine (ICE) vehicles into electric vehicles and uses water-cooled resistors for the braking system. This new offering complements the REOHM range of inverters, which have been developed using state-of-the-art technology and meet the diverse needs of engineers.

The standard BWD 158 series, designed for continuous power up to 5000 W, was selected due to its high overload capacity – up to 33 kW – and its low surface temperature, which can be below ambient temperature in certain applications.

EVs are suitable for operation in areas where low surface temperatures are required, such as in ATEX environments. In such environments, EVs are often preferred over ICE vehicles to minimize the risk of explosion.

“At REO, we believe that not all brake resistors are created equal,” explains Steve Hughes, Managing Director of REO UK. “In harsh environments, it’s crucial to choose a brake resistor that offers better dynamic performance and effective heat dissipation.”

“REO’s indirect cooling system ensures that coolant and current remain completely isolated, but as a separate safety feature, the resistors can be operated for a certain period without coolant flow. During this time, an internal thermal switch can be used to safely and controllably shut down the system.”

Several factors can influence the optimal placement of the thermal switch, such as potential overload conditions, mounting, and ambient conditions. REO engineers can determine the best installation location and temperature for the thermal switch using precise modeling. Furthermore, the resistor is located near the vehicle’s driver, so unwanted cabin heating is not an issue.

Another advantage is that the water-cooled resistor is practically inaudible due to its encapsulated design, unlike conventional resistors, which can generate audible noise at harmonic frequencies of the DC ripple current. This can cause problems in areas where they are in close proximity to people and personnel.

“We are always abreast of the latest requirements, and the low surface temperature of our products, combined with the high IP65 protection rating, allows for use in certain ATEX environments”, Steve continues. “Operational safety and application efficiency are our main priorities, which drives us to constantly research and develop our offerings.”

Another advantage of the highly efficient cooling system is that the resistors can operate in close proximity to other components, and that the resistors themselves are approximately 80 percent smaller than conventional resistors. The BWD 158 series is very compactly built and particularly robust against dust, liquids, and sludge.

For more information about REO’s brake resistors and other products for electric vehicles, please visit our website.