- News

E-Mobility in Practice: Electrically Powered Excavators

The electrification of mobility continues to advance in all sectors of the economy, and REO components are already proving their resilience and reliability daily. These capabilities are particularly important for heavy vehicles: high dynamic forces, adverse environments, and intensive continuous operation demand the highest level of quality.

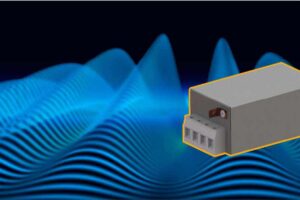

Specifically for these special requirements, REO offers a broad product portfolio with scalable performance. An example of this is the NTT 9339/375/0.06 sine filters, which ensure a clean on-board power supply for electrically powered excavators. Whether in salty air, fine dust, or thick mud, the sine filters guarantee trouble-free and low-maintenance operation. The electric drive works more than twice as efficiently as a comparable diesel engine and, in contrast, is only active when truly needed. Consequently, no energy is wasted during idle phases. This saves resources and enables significantly quieter, more pleasant, and ultimately more cost-effective work. Over their lifecycle, from production to recycling, e-excavators show a 90% better CO2 balance.

“We recognized early on the shift in societal awareness and the resulting potential in the field of electromobility. Our research and development efforts of recent years are therefore already paying off. With our intelligent and smart testing systems for almost every area of electromobility, we offer a globally unique product portfolio.” Jasminka Usein

As part of its electrification strategy, REO has bundled its strengths in the production of inductive, resistive, and electronic components and consistently thought ahead. While many providers purchase technologies, REO can draw on over 95 years of experience – a guarantee for in-house innovation, especially when demanding testing systems are required.