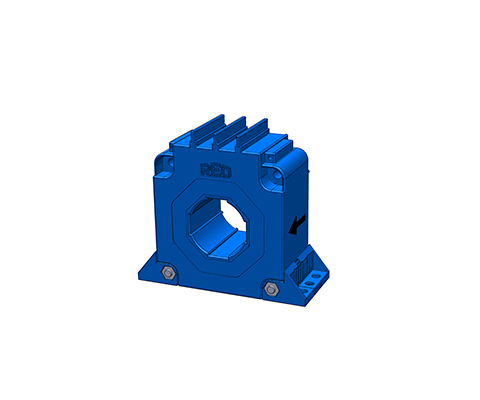

REO TSS reactor with amorphous core

Description

The buck converter chokes as an inductive passive component in the power supply and in power electronics is used to attenuate unwanted frequencies or for saving energy and storage.

The term ‘buck converter choke’ refers to the complete, ready-to-operate unit, comprising the Choke, cooling air guidance, mounting, and connections. The Chokes can be equipped with various cores, enabling customized application based on specific requirements. In addition to iron-based core material, amorphous alloy is increasingly utilized as a core, processed into toroidal cores, cut cores, or special custom solutions.

The use of amorphous materials offers a special combination of high saturation induction (1.56 T) and high permeability. Low remagnetization losses as well as the possibility of use in the medium frequency range (< 20 kHz) and at high powers of up to 500 kVA are additional features of amorphous alloys, alongside their high thermal class.

Advantages

- Lower losses in comparison with grain-oriented sheet

- Can be used in the kHz region

- Equal or higher power ranges with smaller components

- significantly lower weight

- High flux densities

- Usable up to temperature class H (180°C)

- Protection class IP 65

Technical data

- Type of reactor: Up/Buck converter reactor with iron core

- Voltage of the system: 500 – 1100 V

- Max. permissible tolerances: ( -10 % / +10 % )

- Linearity: min. 0.2 mH @ 230 Aeff

- Harmonic currents constantly / Superimposed Harmonics: 60 Ass @ 19 kHz

- Insulation class: H

- Cooling: AF

- Protection rating: IP65/66

- Rated voltage for insulation: 1200 Vdc

- Test voltage: 3.5 kV (50 Hz, 60 s)

| Voltage [V] | 500 – 1100 |

| Rated current [A] | 120 |

| Linearity @230 A [mH] | min. 0.2 @ 230 Aeff |

| Nominal inductance[mH] | 0,2 |

| Resistance [mΩ] | 4,19 @ 20°C

5,83 @ 170°C |

| Losses [W] | ≤ 155 W

@ 107°C |

| Cooper [kg] | 2,2 |

| Weight [kg] | 9,8 |

All data and configurations can be found in our product datasheet.