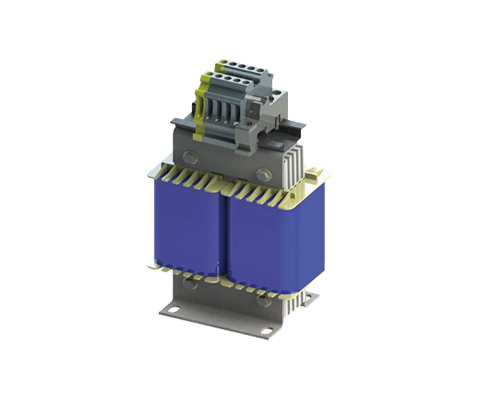

Single-Phase DC Test Choke

Description

Switches must pass many different tests during the approval phase. Some of these tests concern switching behavior under various load conditions; the switch is tested at nominal load, overload, and various power factors. In addition to continuous load, switch-on and switch-off processes are also examined. During these tests, it is crucial not to change the set parameters throughout the entire test.

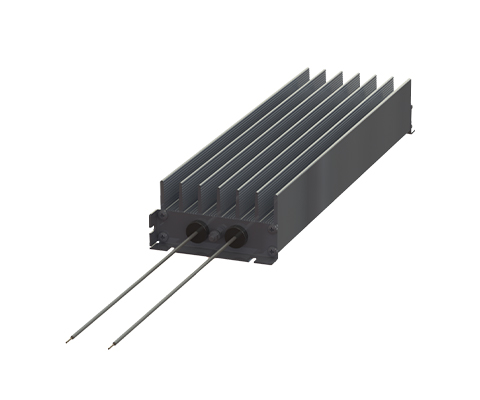

In the past, air-core chokes were used as inductive loads because they are almost non-saturating. However, air-core chokes are larger and have a stronger stray field than comparable iron-core chokes with corresponding magnetic energy. To set the respective power factor (cos φ) value, appropriately adapted resistors had to be connected. To meet all required test points, many different inductive and ohmic loads had to be available.

In the past, air-core chokes were used as inductive loads because they are almost non-saturating. However, air-core chokes are larger and have a stronger stray field than comparable iron-core chokes with corresponding magnetic energy. To set the respective power factor (cos φ) value, appropriately adapted resistors had to be connected. To meet all required test points, many different inductive and ohmic loads had to be available.

Benefits

- Adapted linearity, thus no saturation in the respective operating range

- Multiple taps, only a few chokes are needed instead of many

- Adapted winding resistance, thereby reducing ohmic loads

- Designed for continuous and short-term load

- Optimization of weight and dimensions leads to cost reduction

- High nominal voltage, standard up to 1000V

- Insulation Class: F at 40°C ambient

- Climatic Category: 25/085/21 DIN IEC 68 Part 1

- Max. Winding Temperature: 100°C

- Protection Class: IP 00

- Nominal Voltage: 24 V

- Nominal Current: 0.2 – 4 A

- Inductance: 160 – 125000 mH

| Type | Nominal Voltage [V] | Nominal Current [A] | Inductance [mH] | DC Resistance [mΩ] | Power Loss [W] |

| NPT 892/0.2 | 24 50/60 Hz | 0,2 | 125.000 | 197,3 | 20 |

| NPT 892/2 | 24 50/60 Hz | 2 | 1.200 | 2,855 | – |

| NPT 892/4 | 24 50/60 Hz | 4 | 160 | 2,8 | 64 |

| Type | L [mm] | B [mm] | H [mm] | N1 [mm] | N2 [mm] | øD1 [mm] | øD1 [mm] | A1 [mm] | Copper [kg] | Weight [kg] |

| NPT 892/0.2 | 200 | 148 | 261 | 124 | 120 | 10×18 | 6,2 | 24 | 1 | 2 |

| NPT 892/2 | 240 | 168 | 375 | 144 | 140 | 10×18 | 18 | 44 | 3 | 10 |

| NPT 892/4 | 280 | 173 | 417 | 176 | 143 | 13×20 | 4,4 | 38 | 11 | 38 |